DO YOU HAVE ANY QUESTIONS?

WORKING TIME

- Mon–Fri: 08:00–18:00

- Sat: 08:00–14:00

- Sun: Closed

OUR BROCHURES

GEOPLAST SLABS

Permanent void formwork for light-weight Bi-directional slabs.

New Nautilus light formwork slab generates high structural qualities. It permits the creation of 20 metres wide spans maintaining a reduced weight of the slab up-to 30 %. The result is a very firm bio-directional slab that offers an excellent advantage in terms of seismic response thanks to the reduced weight

Service overview

Geoplast Slabs solutions offer large spans, lightness, seismic mass reduction, optimization, versatility modularity, architectural and acoustic finesse.

SKYDOME

Reusable waffle slab formwork in ABS techno polymer.

SKYDOME system allows the creation of 2-way hollowed slabs which reduce the use of concrete, thus decreasing the self-weight of the structure. SKYDOME reusable elements are used to form decks on which the concrete can be poured. Once the concrete has cured, SKYDOME will be removed, thus obtaining a smooth and pleasing ceiling often left exposed by design.

SKYRAIL

Reusable formwork in ABS techno polymer for one-way ribbed slabs.

SKYRAIL is a reusable formwork system that allows the buildings of one-way slabs with many advantages: structural, weight-reduction; on the worksite, easy and safe installation; building advantages, creation of a technical empty space between the slabs’ ribs. The system is completely walkable and guarantees the workers’ safety.

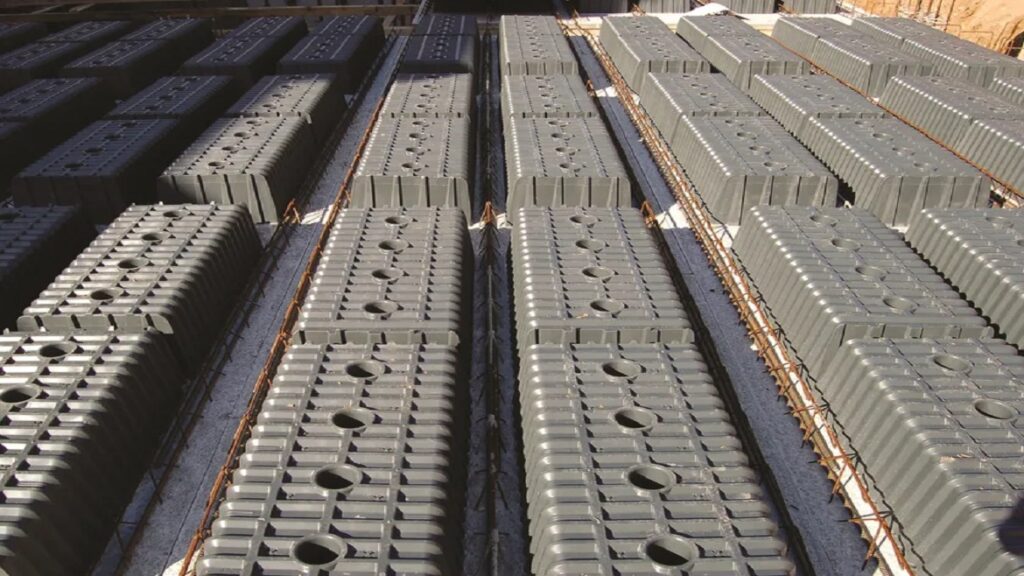

AIRPLAST

Permanent void formwork for light-weight one-way slabs

With AIRPLAST it is possible to build cast on-site slabs such as unidirectional and bi-directional slabs with large spans. AIRPLAST eliminates the use of polystyrene and steel and concrete consumptions are greatly reduced. The high load-bearing capacity and impermeability of AIRPLAST formwork facilitate building operations, allowing the creation of a perfect slab.

As AIRPLAST is made of polypropylene, it can be cut quickly and easily to make offsets. In the upper side of the formwork the cutting point is marked, in this way it is possible to obtain a correct overlapping of the forms. The cut formwork allows also to follow very precisely any possible inclinations of the walls.

GEOSKY

Reusable formwork in ABS techno polymer for full concrete slabs

GEOSKY is a reusable formwork system made of plastic for the creation of flat decks to place the slabs. Its innovative system allows thanks to the main beam with a sliding wedge, a quick installation and disarming. Moreover, it is also possible to reduce the rotation of the formwork material in the construction site, in order to accelerate the pouring stages.

The system consists of GEOPANEL panels 1200 mm x 600 mm and 3 plastic beams that should adequately be placed on H20 wood traditional trusses that allow the early stripping of the formwork system.

APPLICATIONS:

MULTI-STOREY BUILDINGS

The increasing of the seismic response of a building starts from a correct planning of the bearing structure. The construction of a firm slab whose load doesn’t excessively affect the pillars and the foundation is a fundamental aspect; NEW NAUTILUS EVO system completes these concepts by creating a very firm bio-directional slab with a reduction of its self-weight up to 30 %.

MULTI-LAYER BUILDINGS

The self-weight of concrete slab formed with SKYDOME is up to 30 % lower than a full concrete slab. This is a distinct advantage as it reduces the oscillation of a building during an earthquake, thus increasing its structural resistance. Moreover, the weight reduction of the slab allows design and cost advantage for the overall concrete frame.

CAR PARKS

When building basement car parks or multi-storey car parks, the main aspect is the obtainment of the highest number possible of stalls. Through the building of bidirectional slabs and their lightening with NEW NAUTILUS EVO, it is not only possible to create larger spans than the traditional solutions but also to optimize the pillars position in order to create as much parking and manoeuvring space as possible.

MULTI-STOREY CAR PARKS

A waffle slab formed with SKYDOME virtually eliminates the need for drop beams and column heads. This makes the soffit completely flat, removing all obstacles to the passage of tubes, plumbing and all systems, making their installation easier and more economical.

POPULAR QUESTIONS

Our Featured projects

Shreveport, Bossier City

This twin-tower condo projects is one of the largest new residential building projects in the Puget Sound area, with 500...

Learn More